How to Solder a TT Motor

The aim of this guide is to teach MiniFRC teams how to solder wires to their TT motors by following the recommended steps.

The aim of this guide is to teach MiniFRC teams how to solder wires to their TT motors by following the recommended steps.

- Assemble the components required to solder the TT motor.

- Clear workspace of all unnecessary components to ensure a clean soldering job. This includes: the included wheel, zip ties, and other distractions. NOTE: Always follow proper personal protection guidelines, Alfredo encourages safety!

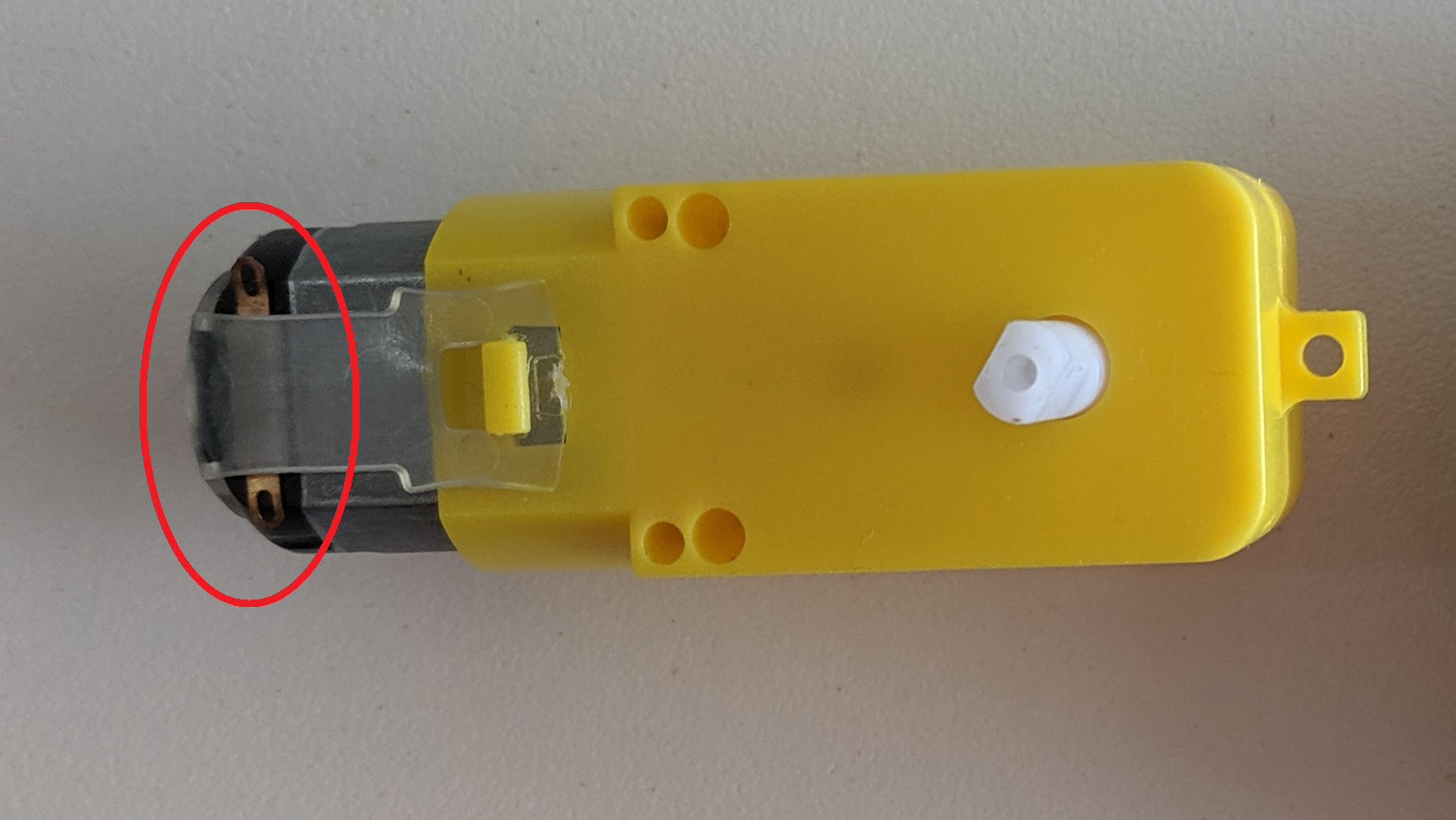

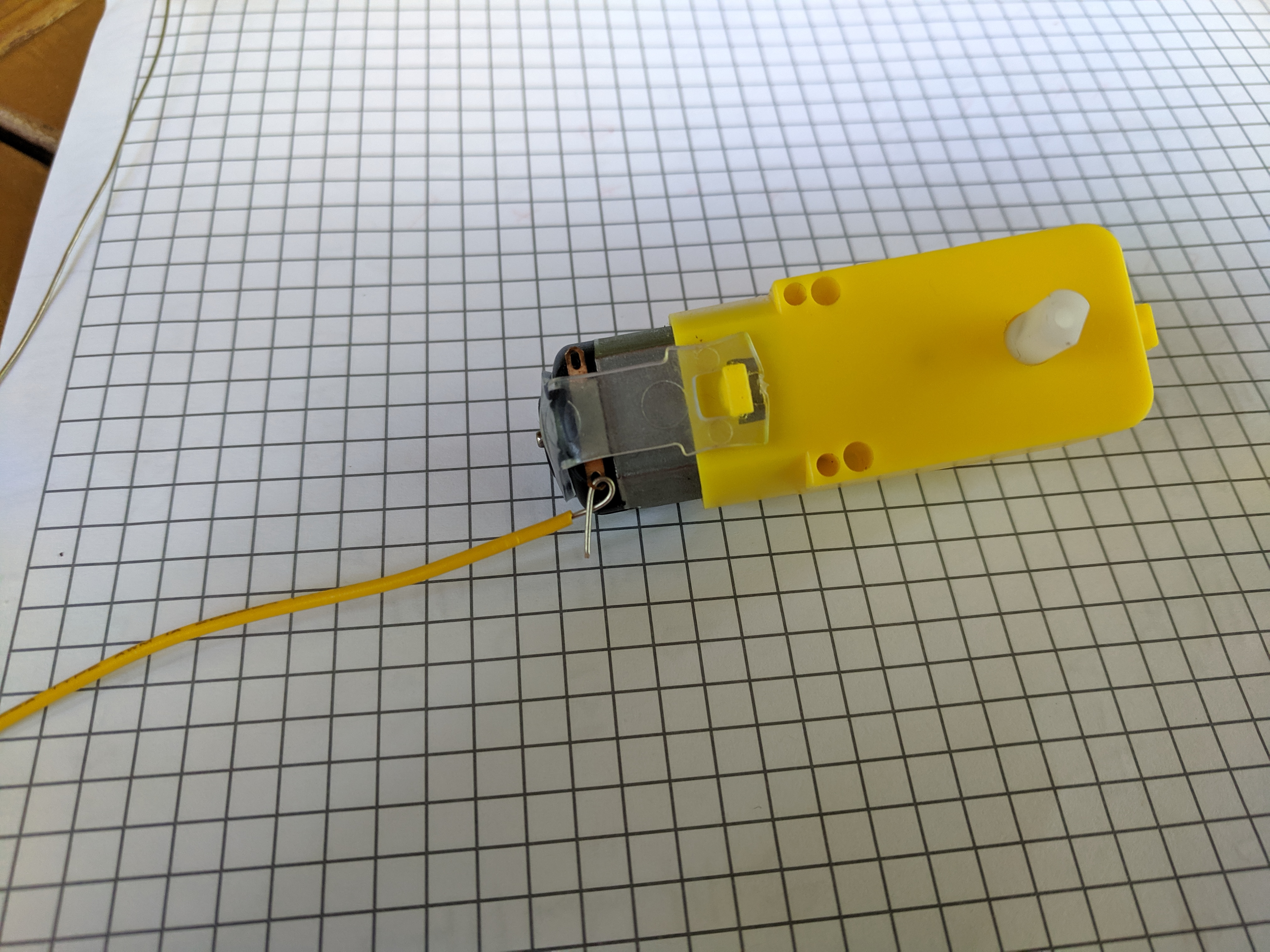

- Locate the two “ears” on the motor as shown below.

- Cut an appropriate amount of wire to connect the motor to the microcontroller. Make sure the amount cut does not result in the wire being taut, usually a few inches is enough; after all, the wire can be cut shorter but not longer.

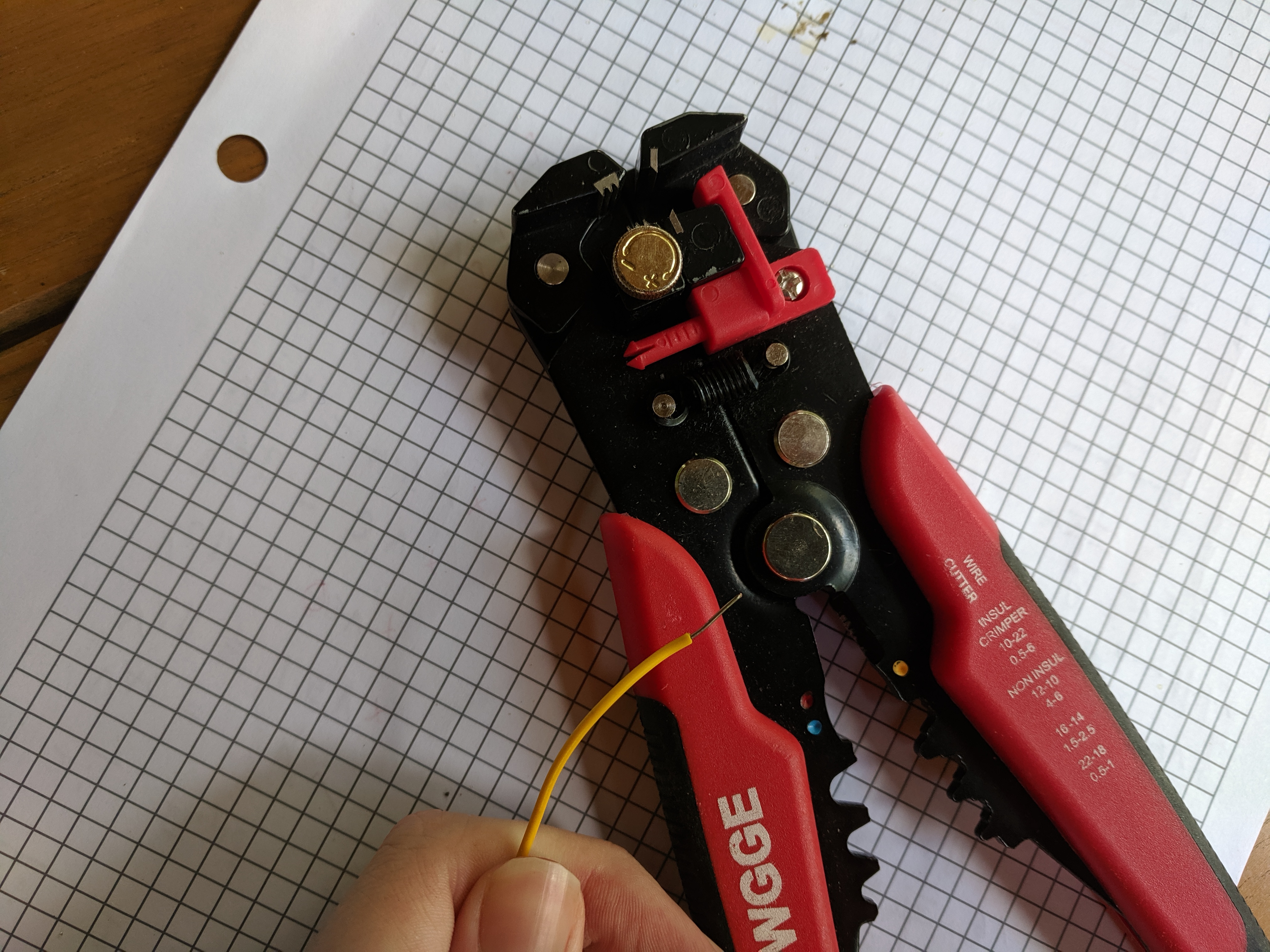

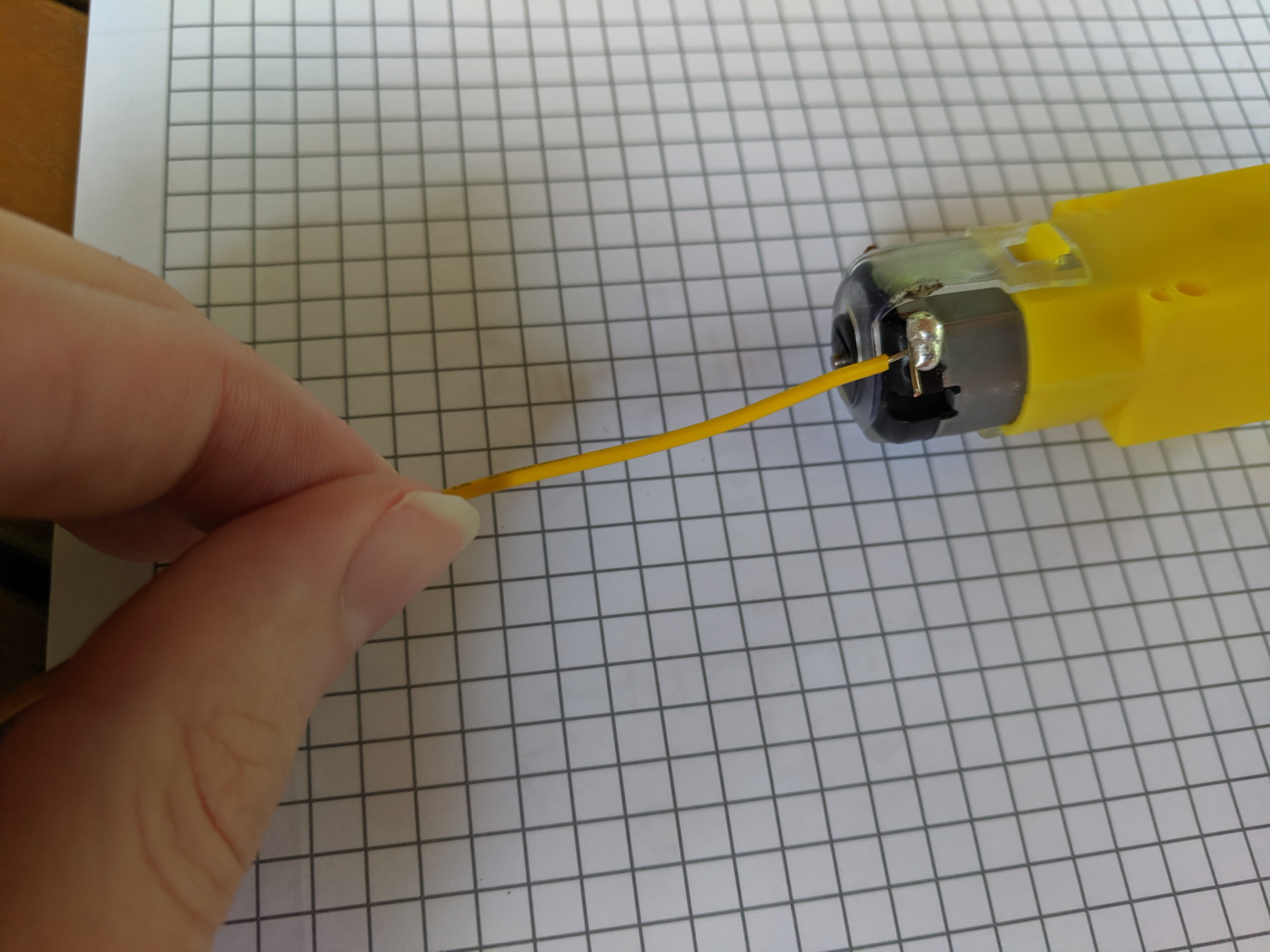

- Strip the ends of the wire so that about the width of a fingernail of exposed wire is showing.

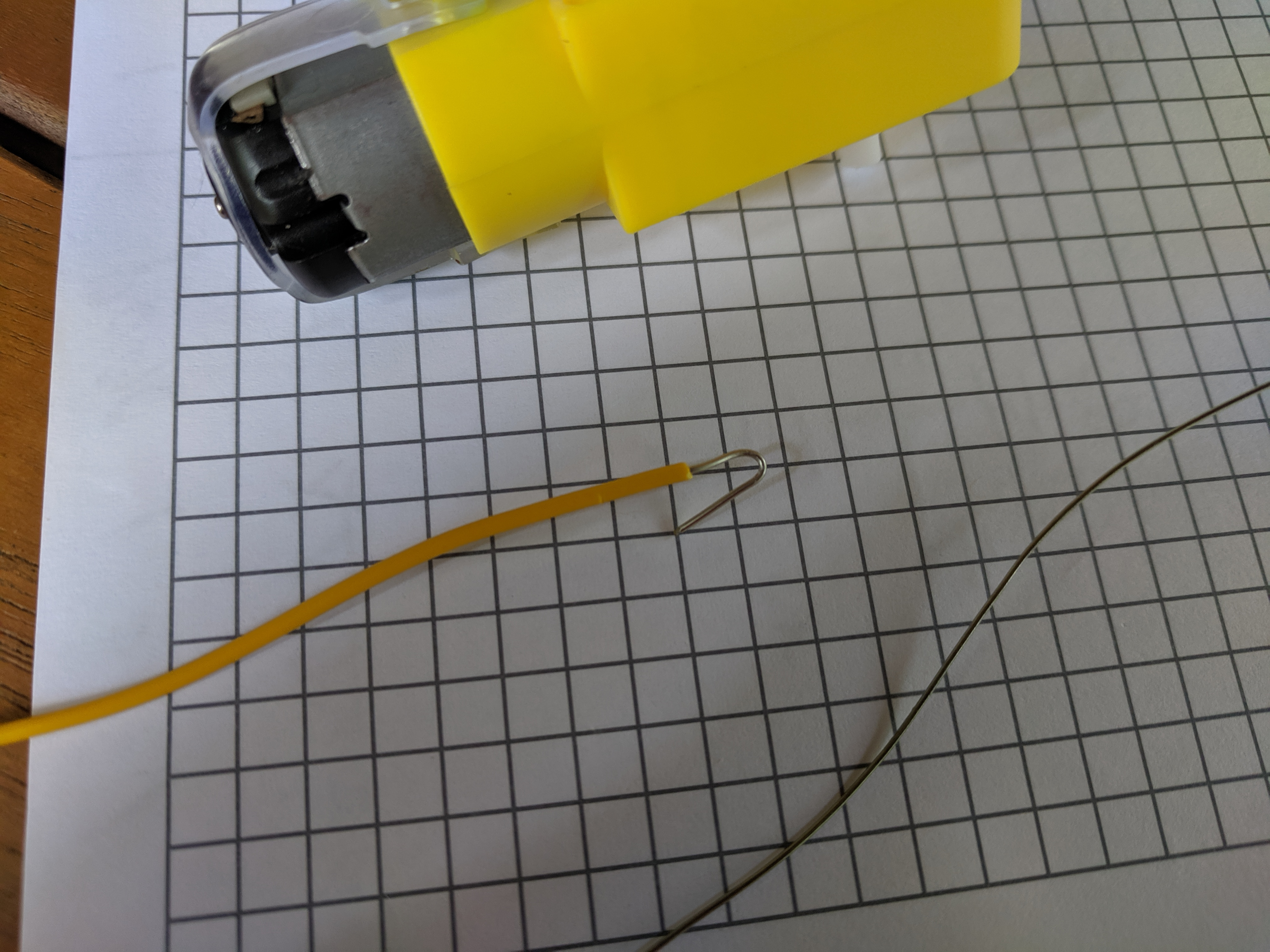

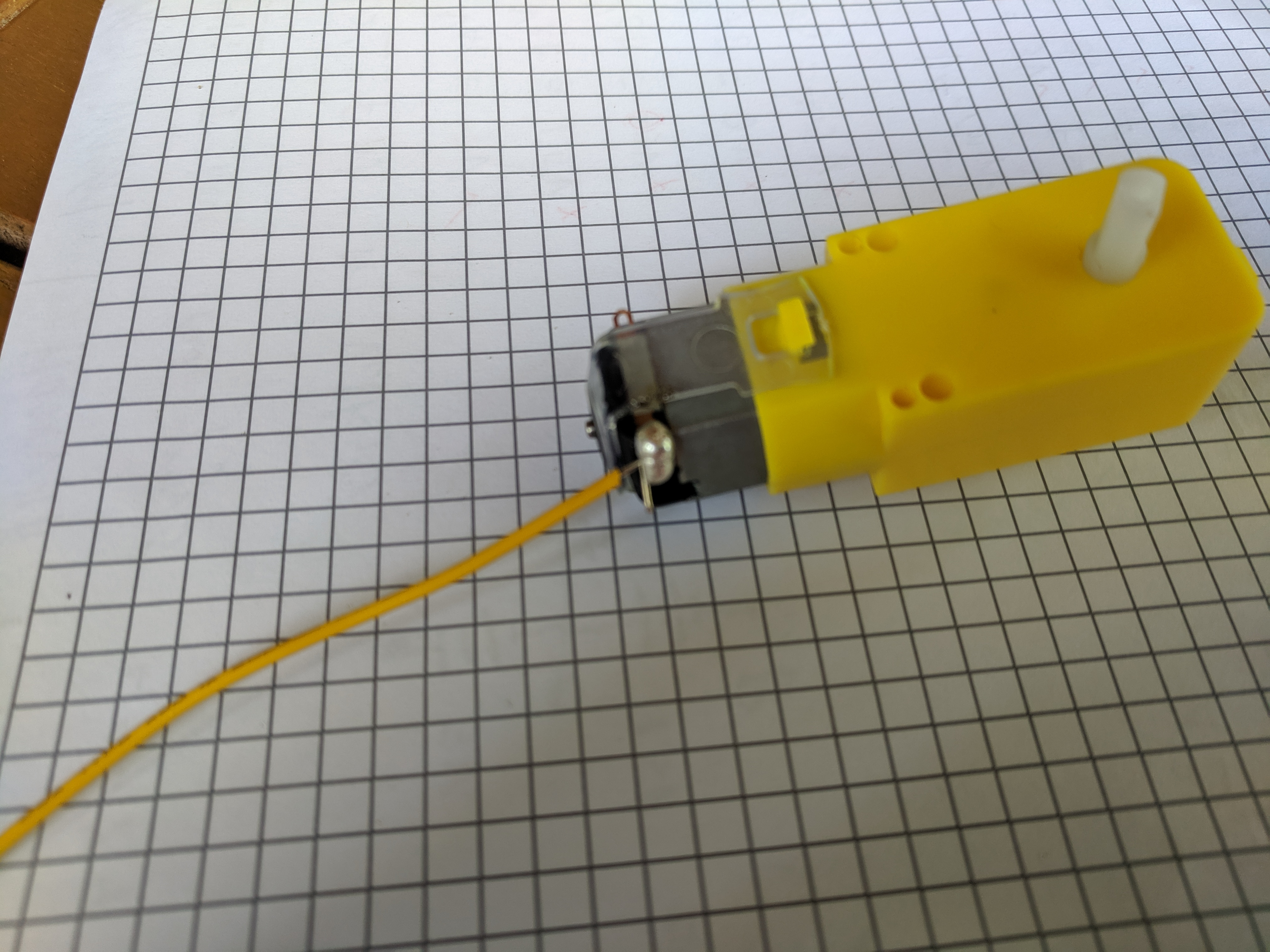

- Bend the wire ends into a hook shape as shown. This will be part of a technique known as a splice and can reduce the chance of the wire coming undone.

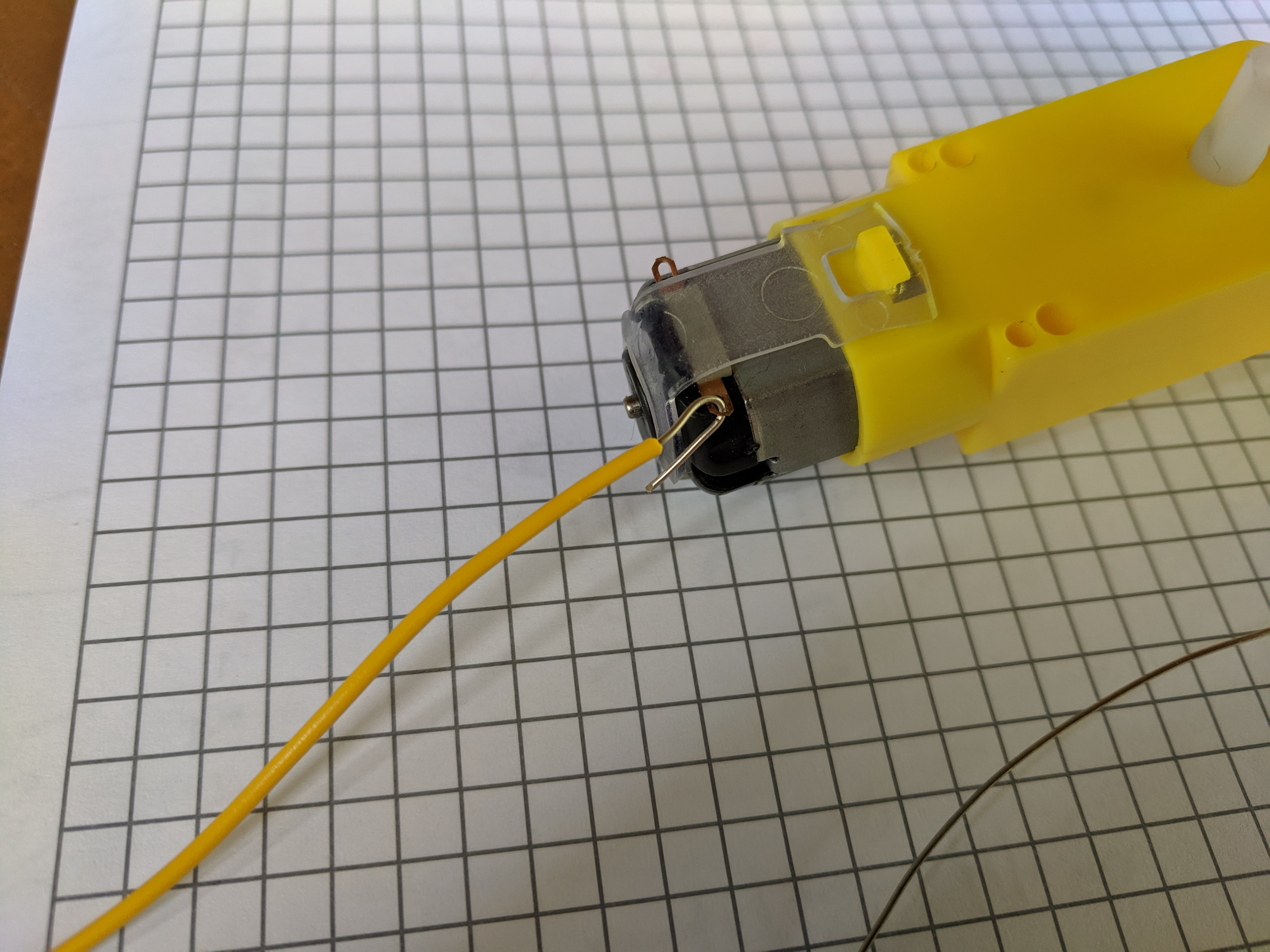

- Connect the hooked end to the ears of the motor as shown.

- Carefully close the hooked wire into a loop shape.

-

Once the solder has warmed up (about 5 to 10 minutes if the soldering iron used does not display temperature) begin soldering in the following steps.

- Apply soldering iron to motor ear

- Apply solder to motor ear

- Allow solder to flow and connect the ear to the wire loop

- Take solder wire off of ear

- Remove soldering iron from ear, unplug, and safely store while not in use

- Test the soldered joint by tugging (LIGHTLY, as the ears are very fragile) on the wire to make sure that the solder properly covered the wire and ear.

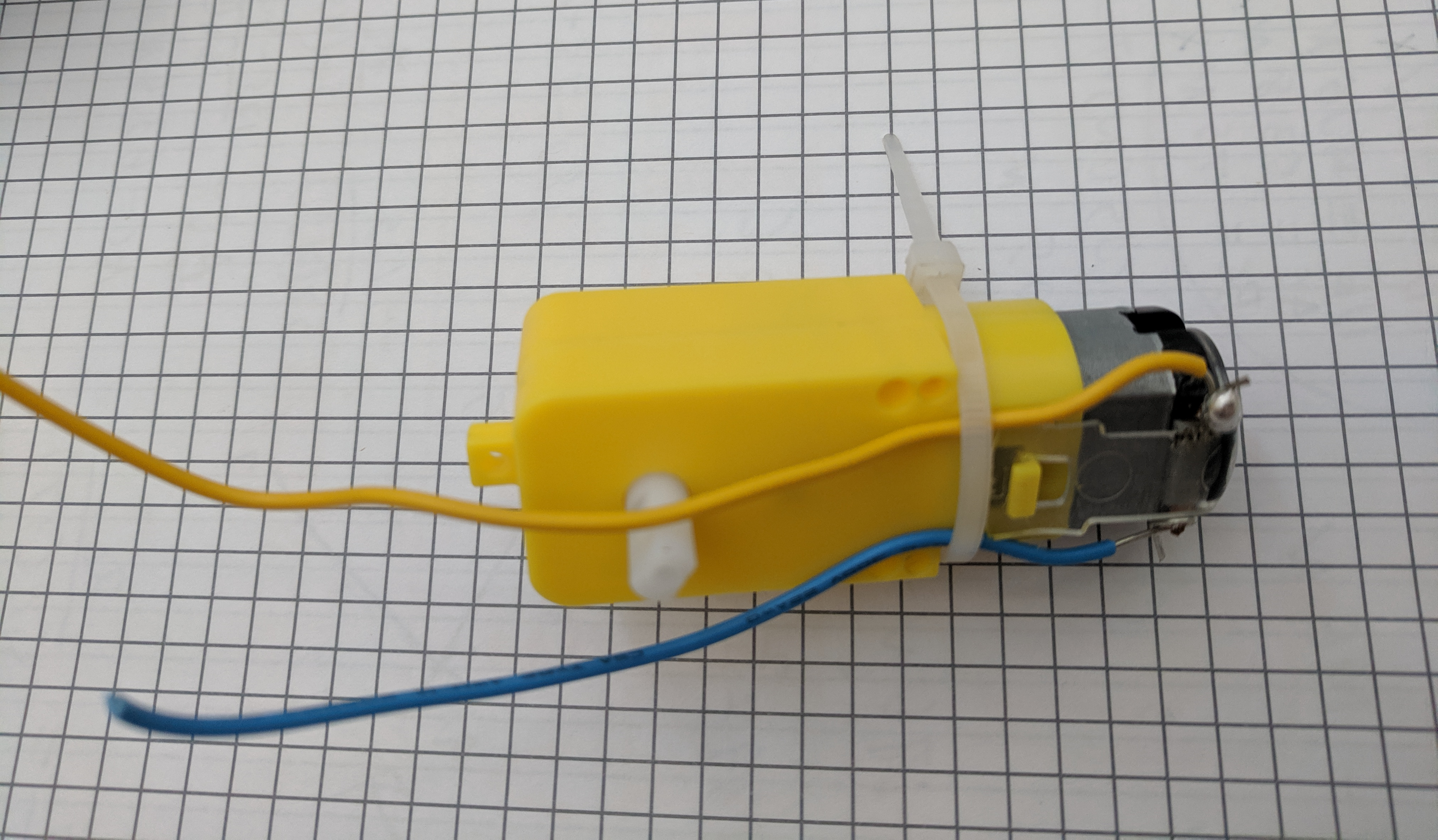

- Finally, protect your motor’s ears with ‘strain relief’. Teams who skip this step will often lose robot functions during matches when their motor ears inevitably get ripped off by loose wires. Try to avoid this whenever possible by adding strain relief as shown below.

Congratulations on your newly soldered motor!